Typically a big extractor fan is required in the various industries, including manufacturing and warehouses / Commercial kitchens. The modern fans are not just normal fan rather they have been designed to withstand high-pressure airflows that makes them a perfect tool along with their cooling impact for creating an optimal working environment of the employees and enhancing their overall efficiency. Subsequent to this initial application, these fans were also used in industrial settings and have helped to modernize ways that buildings can keep indoor air at an acceptable standard.

Little do people know, extractor fans are the industrial equivalent of workhorses-they operate effortlessly in the shadows under a singular working force: to draw stale moist or contaminated air out from an indoor space and let fresh outdoor come in. Industries depend a lot on high-temperature, gas-based processes as this is very crucial and we must maintain the efficiency in carrying out these methods. These fans contribute as well to increased performance of a business, enhancing air quality and delivering the airflow.

Furthermore, its most common properties also demand functioning sizes of extractor fans for creating the air having high quality. These are in high volume and Blowersdoor have them for the pros. This is crucial in industrial settings where conventional ventilation/architectural systems cannot cope with the range of substances and conditions met, hence sensing. For this reason, the use of massive extractor fans has traditionally been seen as one of the best ways a business could improve its ventilation.

Repeatedly, you will certainly be greatly shocked to appreciate the advantages of having those substantial extractor fans fitted not far off commercial kitchens. Not only they save energy (as noted earlier), but fans like these offer several great qualities for already hot and active kitchens, including benefits that are ideal to a working kitchen. Beyond providing healthier indoor air, the fans also remove steam, smoke and cooking smells while keeping their HVAC systems running more efficiently - all of which translates into long-term energy savings that will easily offset any costs on those fan replacements. So this way the cooking will be a great process and you get saved from those huge utility bills.

Air quality management is a necessity, but if you own any large commercial or industrial space; only Bright Extractor Fans can help you solve that problem. This, in turn makes the fans a silent vigilante as they dispose off all dust fumes and chemical vapors efficiently without letting it scatter around which seems to be harmful for housed workforce. In the range of woodworking shops, metal fabrication units and chemical processing plants; these fans work as the prime manner to maintain the safety codes ergo render safe working atmosphere for workers.

This high specification applies to fanlights as well, since warehouse interiors can get extremely hot in the summer so are often accompanied by large extractor fans needed not only for ventilation but also to provide a cooling breeze that keeps workers more comfortable. During summers, it also helps to exhaust hot air from the warehouse and cross-ventilation keep your staff cool as well damages of heat & humidity free storage. Mainly these fans are used for maintaining proper control of temperature and humidity to the desired level so that a warehouse then becomes controlled enough for operations other than those in transit as well product preservation.

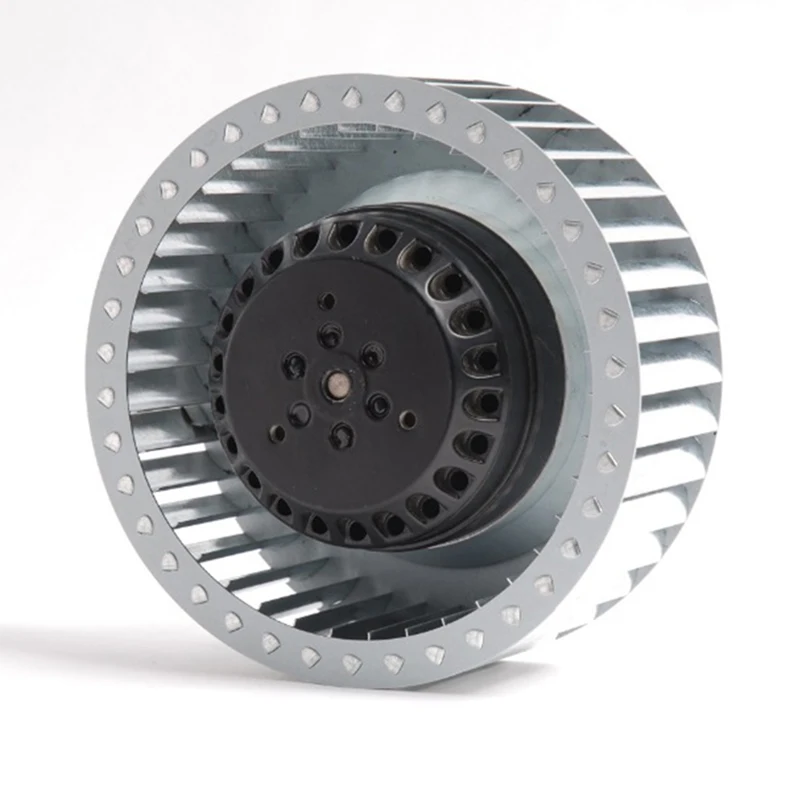

High bay extractor fans are crucial for any industrial environment This type of commercial high bay fan is an ideal solution to all your airflow control, safety or air quality problems. That is why they are the best choice in any business -they not only care about paying better places to work and improving our use of energy, but also that protect us from environmental pollution. These fans are highly technically developed and growing with the modern technology to provide high performance for many industrial circumstances.

These large industrial extractor fans help make changes in an industry by removing the stale, humid or polluted air and replaces it from fresh out door air. An ongoing supply of fresh, ionized air vents away fumes and dust particles produced by these industrial processes so that they pose no health threat to staff members working on the shop floor while keeping them at a comfortable temperature. The fact that they can process large quantities of air in one go means they are invaluable within environments where traditional ventilation would have struggle, therefore increasing Operational efficiency and safety.

Care must be taken to determine the ideal extractor fan for large sizes, so that innovation and efficiency are not impeded. Airflow capacity is the most important consideration, ensuring that fans are rated high enough to move large quantities of air with ease. Another important consideration is energy efficiency, with high-efficiency motors lowering long-term operating costs. The corrosion-resistant material is, of course, an added bonus for the fan lasting through tough industrial conditions. What is more, to make a workplace environment proper in partitioned offices near industrial regions or similar places where enclosed noise develops need for sound reduction features. Finally, simple maintenance—everything from easy to reach filters and components, so that your machine is rarely ever down for a cleaning or repair.

In other words, big extractor fans save energy- something that would be a huge deal among commercial kitchens where it can get extremely warm and humid. In addition to improving indoor air quality, these fans also help relieve the burden on HVAC systems that would otherwise use more energy for cooling and dehumidifying. This translates to significant energy savings, making for a more environmentally friendly kitchen and reduced overhead with utility costs.

The air quality within industrial and commercial spaces is known to directly impact the health and productivity of workers. One of the major factors in keeping air clean is large extractor fans which help to remove dirt, fumes and chemicals vapours so they do not build up causing a potential health risk. These fans act as the first line of defense in industries like woodworking, metal fabrication or chemical processing; where particulate matter and exposures to toxic gases are common which help compliance with occupational safety standards leading a healthier workforce.

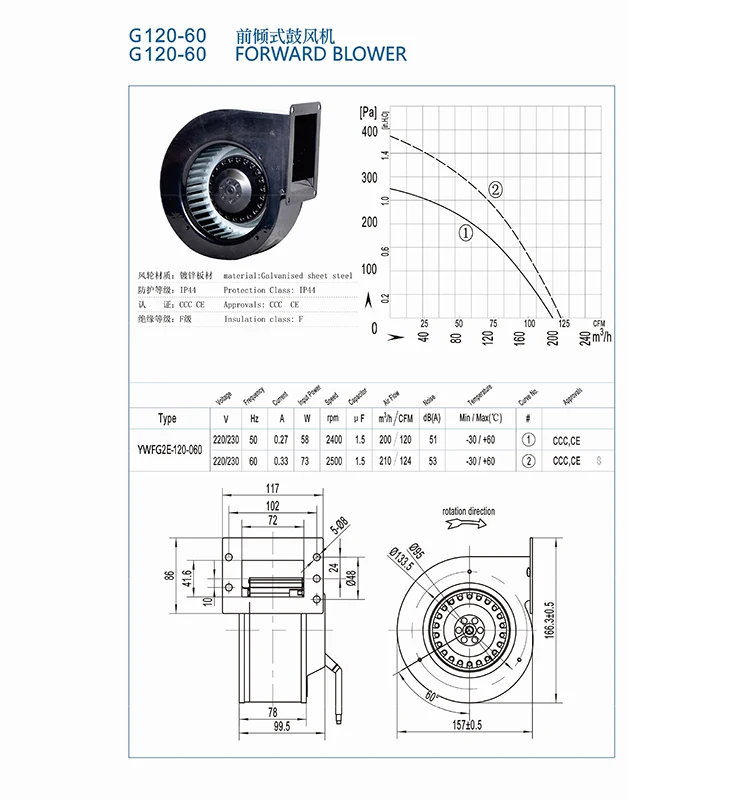

Beron motors is certified by CE ROHS UL CCC SGS as well as others certificates. Additionally, we have a Wind tunnels and large extractor fan.

large extractor fan Motor manufacturing firm covers 15000 square meters two factories. Beron motor 3 product ranges comprise than 2000 models as well more 10000 kinds spare parts accessories meet customer's requirements full terms. Beron Motor laboratory located renowned university.

Beron motor promises samples time 2-3days, large extractor fan, and triers orders. within 25 days bulks orders. Our products are exported over 50 countries and provides services to more 5000 clients worldwide.

Beron large extractor fan main product EC DC AC External Rotor Fans Full ranges. products widely used Fresh air systems, heating, airs conditioning ,refrigeration, air purifications, telecommunications, electric powers etc.