Proper ventilation is critical for both the workers and equipment in an industrial environment, as one should be able to breathe fresh air wherever they are working. Industrial exhaust fans are an incredibly efficient way in which to do this. The powerful fans help in removing stagnant air and infusing fresh, clean air into the workspace; thereby improving overall health & comfort within your areas.

Top-Rated Industrial Exhaust Fans, What To Know [March 2021]

The market for industrial exhaust fans are widespread offering a variety of choices. But, all fans do not perform with the same efficiency Industrial exhaust fans that are rated highest often have powerful ventilation accompanied with minimal noise production.

Their 56 Inch Industrial Exhaust Fan by VES Environmental Solutions is an example of the latter. The fan is built to last, with aluminum blades that can move a large amount of air quickly in tough industrial conditions. Furthermore, it has a corrosion-resistant coating which means that you can use it outdoors.

Soler & Palau TD-MIXVENT Inline Duct Fan Another great choice is the Soler & Palau TD-MIXVENT Inline fan. Easy To Mount In Tight Spaces This small, versatile fan can be mounted in most orientations. With a built-in speed controller, the fan's velocity can be tailored to meet individual requirements at any point in time.

Picking the right industrial exhaust fan is a big investment and should not be taken lightly. To help facility managers navigate this decision-making process, read on for expert advice:

Calculate the required airflow: To find out what is the maximum ventilation capacity needed in your structure, it is important so you can select between a range of different sized and powered exhaust fan.

Industrial Exhaust Fan Best Placement because best industrial exhaust fans placement You need to identify where you really want airflow in your room and then place fans accordingly.

This is another vital expense as the cost of industrial exhaust fans can be changeable depending on size and type Hence, it is not just the purchase price that facility managers should consider during decision making but also installation and maintenance costs.

Industrial exhaust fans with an energy-efficient design are a highly viable option for facility managers who want to save on expenses related to lower energy usage and operational costs. See also: some cars popular for being efficient with their energy.

Canarm Direct Drive Wall Exhaust Fan: Super energy-efficient, this fan comes with a fully enclosed thermally protected motor and an automatic shutter mechanism for more controlled use of energy.

TPI Corporation CE36D3HBD Direct Drive Exhaust Fan: Here is a 36 inch fan that comes with an enclosed motor for reduced noise operation as well as energy efficiency to add to the long life of it.

Industrial exhaust fan installation seems frightening, especially to those who are unskilled at electronic and mechanical systems but when it comes down between doing a DIY job or calling in the professionals your choice is so important. ConsWhile a DIY approach may save money on the installation costs, it is also important to admit that there can be some risks involved with incorrect installations.

Using a professional for your installation provides you extra experience and skill, better tools with which to install the floor and peace-of-mind that they will do it right! When professionals install the manufacturer, they put it in place with minimal risk of accidents and injuries

Choosing the right industrial exhaust fan is an important decision as it affects directly on health and safety of people inside facility. Key Facets to Weigh For Facility Managers in this Selection

Airflow Rate Requirements: For there to be proper air circulation in the facility, it is important that an effective fan for a sufficient airflow capacity can also properly suit into your dust extraction system.

Once all air quality issues are resolved (including leaks and pressure imbalances) the placement of industrial exhaust fans is essential to optimize ventilation efficiency. Key air flow areas need to be identified and the correct fan placements are critical.

Noise level: The noise produced by an industrial exhaust fan is of critical importance in locations where communication matters. In a professional setting, selecting fans with low noise emissions is highly recommended.

So to sum up, ventilation in industrial premises is highly essential and it contributes to the well-being of occupants inside. Correctly select, the use of industrial exhaust fans can greatly improve ventilation efficiency, reduce energy consumption to achieve a relaxed work environment. There are many different features that to consider for facility managers: size, power, placement and noise level when selecting a fan. If you are unsure, using professional installation services is one way to guarantee a safety and good setup.

Beron motor promises times for sample 2-7 days, industrial exhaust fan and trier orders and within 25 days for mass orders. We offers services to than 5000 customers around the globe and exports to 50 countries.

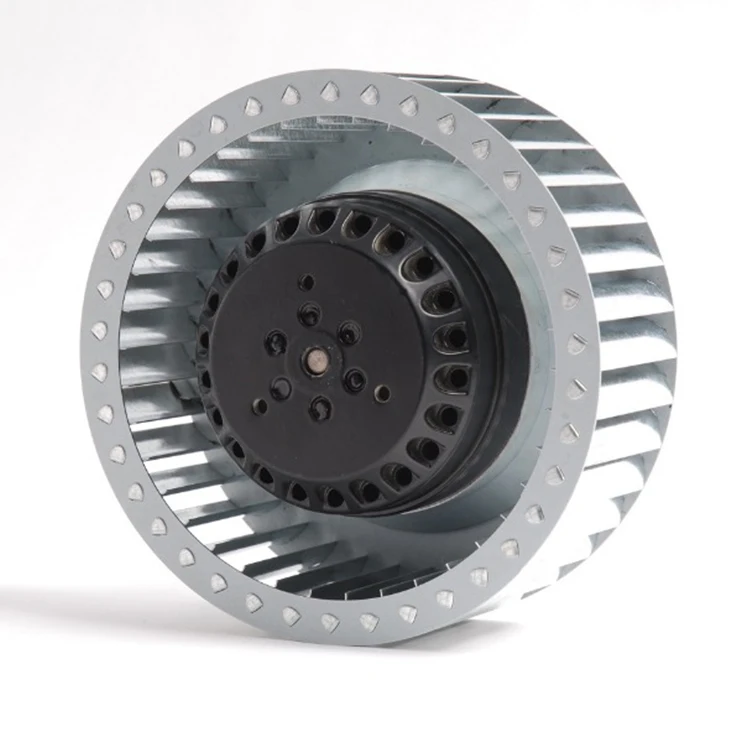

Beron Motor's industrial exhaust fan product line EC DC AC External Rotor Fans Full Ranges. products widely used Fresh air system, heating, air conditioning ,refrigerations, air purifications, telecommunications, electric power etc.

Beron motor manufacturer industrial exhaust fan 15000 square meters two factory centers. Beron motor manufacturer three product lines, including than 2000 models more 10000 different kinds spare components accessories can meet every customer's needs complete terms. Beron Motor laboratory located renowned university.

Beron motors is certified through CE industrial exhaust fan and UL CCC SGS and others certifications. Additionally, we have a Wind tunnels as well as a sounds test lab.