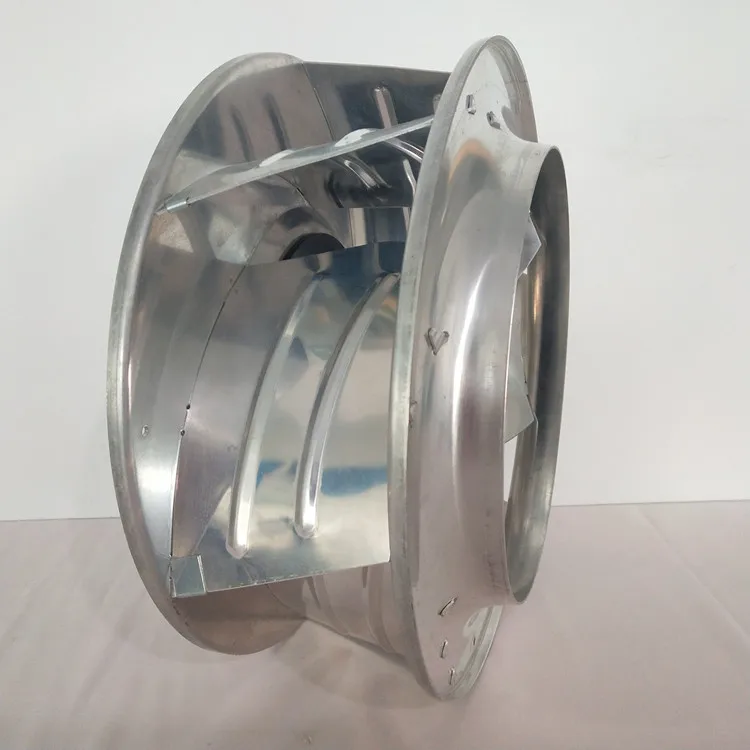

Backward curved centrifugal fans are designed with blades that curve in the opposite direction of rotation, enhancing efficiency by reducing the amount of energy lost to turbulence. Because they allow the handling of large air volumes at reduced power consumption, these fans have found significant application in both industrial HVAC systems.

Backward curved centrifugal fan is more like a new thing instead of radial fan. The main reason for this is because they require less maintenance, thus allowing businesses to save their time and resources due to that aspect. Moreover, they can operate more efficiently which is extremely important for their future development in the market. These fans consume large amounts of air with small amount of power and have a high pressure drop designed into them, making them ideal for many different applications

They have backward curve blades that allow the blades to be turned by the flow of air towards it; this has been useful in ensuring that there is a laminar airflow. This helps both in enhancing air movement as well as reducing noise levels. The other features include blade with UV protection, which are flame retardant, and backward facing hence enabling better operation using minimum noise.

A range of industries benefit from backwards curved centrifugal fans. Most importantly these fans are energy efficient. They move large quantities of air at high pressures but consume lower electricity. Furthermore, Beron-motor backward curved centrifugal blower saves on energy and therefore reduces running costs for companies in general.

Fans with this design make almost no sound while on duty; good when you need silent atmospheres per each unit (fan). For instance, offices, schools or hospitals would want something like these since Beron-motor backward centrifugal fan operates silently under such conditions where calmness is crucial and it does not disturb anyone around.

It’s very important to choose an appropriate backward curved centrifugal fan for your HVAC system so it can function at its best condition; several considerations must be done before choosing one among those available out there such as how much airflow needs to be moved, ductwork involves pressures and solutions’ compatibility within HAVC components etc., all affecting performance of any such machine.

Beron Motor's primary product line EC DC AC External Rotor Backward curved centrifugal fan Full ranges. products widely used Fresh air system, heating, air conditioning ,refrigerations, air purifications, telecommunications, electric power etc.

Beron Motor is accredited by CE ROHS CCC SGS and CCC Backward curved centrifugal fan, CE ROHS, UL CCC and others certifications. We also have a Wind tunnels as well as a noises testing labs.

Beron Backward curved centrifugal fan manufacturing firm occupies 15000 square metres two factory centers. Beron motor offers three product lines include 2000 models, as well more 10000 kinds spare components accessories that the requirements every customer full terms. Beron Motor laboratory located renowned university.

Beron motor promises samples time 2-3days, Backward curved centrifugal fan, and triers orders. within 25 days bulks orders. Our products are exported over 50 countries and provides services to more 5000 clients worldwide.

Recent technological development has also seen the improvement of Backward Curved Centrifugal fans. This new and innovative Beron-motor centrifugal fan backward curved is quieter and can run for longer than its predecessors. Presently, fan blades produced using computer-aided designs (CAD) and computational fluid dynamics (CFD) remain the best in class. These are what contribute to an increase in airflow as well as reduce noise while ensuring the product being economical energy.

Among other things, industrial fan blades have also benefitted from new materials such as composites and polymers. For instance, they can prevent rusting and corrosion hence saving lives of fans. These lighter fans’ weights are possible due to better design practices and non-metallic materials, making installation and repair easier than before.

Installing backward curved centrifugal fans in the HVAC system require them to be installed correctly so that there is no return on its efficiency or performance. Before you add them, there are several things that you need to know such as which fan for the airflow requirements and pressure levels but considering ductwork designs. This provides a better flow of air and control of pressure with additional benefit of less energy used.