عند الحديث عن نظام التكييف والتدفئة، فإن المروحة الدورانية ذات المنحنى الأمامي هي مروحة شائعة وأداة مهمة. تلعب دورًا حيويًا في تدوير هواء أي منطقة، سواء كانت منازل أو مباني تجارية. فهي تسحب الهواء من الغرفة ثم تنفخه عبر مجموعة من الأنابيب. طريقة عمل المروحة في الواقع رائعة، حيث تستخدم قوة خاصة (لا تسألني ما هي لأنني لا أعلم) لدفع الهواء نحو الخارج من مركز شفرات المروحة. هذا يولد تدفق هواء يسمح للناس بالبقاء في بيئة مريحة وطازجة.

هناك العديد من المزايا عند استخدام مروحة هوائية ذات منحنى أمامي لنظام تكييف الهواء الحالي الخاص بك الذي يعمل بالأنابيب. الميزة الرئيسية هي أنها توفر الطاقة. هذا يجعلها استثمارًا فعال التكلفة يمكن أن يقلل من فواتير الطاقة ويساعدك على توفير المال! فهي توفر لك المال وتكون أكثر خضرة - مما يعني استخدام طاقة أقل! بالإضافة إلى ذلك، تم بناء المروحة بحيث تكون أكثر صمتًا مقارنة بأنواع أخرى من المراوح. لقد تم تصميمها بنظام تقليل الضوضاء لضمان أنها هادئة أثناء التشغيل، مما يضمن ألا توقظك المروحة من نومك وتمكينك من التركيز والعمل في صمت. هذا سيوفر لك أيضًا منطقة أكثر هدوءًا، وهو دائمًا إضافة رائعة!

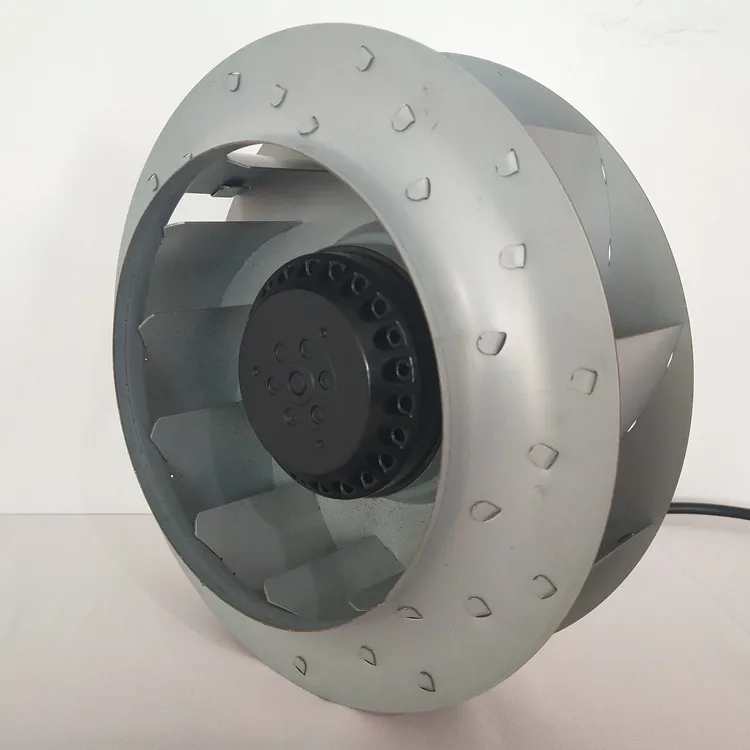

يتكون مروحة الطرد المركزي ذات المنحنى الأمامي من أربعة أجزاء أساسية تتفاعل مع بعضها البعض لتساعد الجهاز على تحقيق الأداء الأمثل. المحرك، والمروحة، والغطاء، والمدخل. المحرك هو الجزء الذي يدفع ويوفر الطاقة لمروحة للعمل. لن تعمل المروحة حتى بدون المحرك. جزء آخر مهم هو المروحة، ومهمتها هي سحب الهواء وإخراجه من المروحة. إنها تولد القوة اللازمة لتحريك الهواء بشكل أساسي. الغطاء هو الحasing الذي يحيط بشفرات المروحة. وبالتالي، فإنه يساعد في التحكم باتجاه تدفق الهواء إلى حيث يجب أن يذهب. وأخيرًا، المدخل هو الفتحة التي يؤدي إليها دخول الهواء إلى المروحة. جميع هذه الأجزاء معًا تضمن أن تعمل المروحة بسلاسة.

الصيانة الدورية مهمة جدًا إذا كنت ترغب في الحفاظ على عمل مروحة الطرد المركزي ذات الشفرات المنحنية للأمام بشكل جيد. لذلك، تحتاج دائمًا إلى صيانة مناسبة للمروحة والتي يمكن أن تساعد الجهاز على العمل بكفاءة وطول عمره. تنظيف الشفرات والهيكل بانتظام هو أحد أهم الأشياء التي يمكنك القيام بها. مع مرور الوقت، يمكن أن تتراكم الغبار والأوساخ على شفرات المروحة السقفية مما يعيق وظيفتها الصحيحة. الشفرات القذرة تؤدي إلى تقليل تدفق الهواء ومروحة أقل كفاءة. بالإضافة إلى التنظيف، يجب عليك أيضًا فحص أجزاء أخرى من المروحة. يتراوح ذلك بين فحص الأحزمة والbearings للتأكد من أنها سليمة. كما يُنصح بتزييت المحرك جيدًا حتى يعمل بسلاسة. إذا كان لديك أجزاء متآكلة أو معطوبة، قم بتغييرها فورًا لتجنب أي مشاكل أثناء التشغيل.

شهدت السنوات القليلة الماضية تطورات تقنية مثيرة في مجال تقنية المراوح المركزية ذات المنحني الأمامي. على سبيل المثال، أحد الفوائد الرئيسية هو الأداء فيما يتعلق بسرعة دوران المروحة. وبالتالي، يمكنك ضبط المروحة وفقًا لذلك، إما بزيادة تدفق الهواء أو الحفاظ على صمتها أثناء التشغيل بسهولة. هذه المرونة توفر الطاقة وتمنح البيئة الراحة. لقد تم تصميم أحدث المراوح المركزية ذات المنحني الأمامي لتكون نماذج أكثر كفاءة من حيث استهلاك الطاقة. غالبًا ما تحتوي الوحدات على تحسينات في الأداء مثل محركات السرعة المتغيرة التي تمكن المروحة من العمل بسرعات متعددة، بالإضافة إلى المحركات الإلكترونية المغناطيسية التي تستهلك طاقة أقل. هذه التحسينات لا تعني فقط أن المراوح أكثر لطفًا على فواتير الطاقة الخاصة بك، ولكن أيضًا على الأرض!

شركة بيرون موتور لتصنيع المراوح الطاردة المركزية ذات المنحنى الأمامي تبلغ مساحة منشآتها ١٥٠٠٠ متر مربع، وتضم مركزين تصنيعيين. وتشمل منتجات شركة بيرون موتور ثلاث فئات رئيسية تضم أكثر من ٢٠٠٠ طرازٍ، وأكثر من ١٠٠٠٠ نوعٍ من قطع الغيار والملحقات لتلبية احتياجات العملاء بكافة شروطها. ومختبر شركة بيرون موتور المنزلي يقع في جامعة عالمية مشهورة.

تشمل المنتجات الرئيسية لشركة بيرون موتور المراوح الطاردة المركزية ذات المنحنى الأمامي من النوع EC وDC، والمراوح ذات الدوارات الخارجية، والتي تغطي نطاقًا واسعًا من التطبيقات. وتُستخدم هذه المنتجات على نطاق واسع في أنظمة تهوية الهواء النقي، وأنظمة التدفئة وتكييف الهواء والتبريد، وأنظمة تنقية الهواء، والاتصالات السلكية واللاسلكية، والطاقة الكهربائية وغيرها.

تحصل محركات بيرون على شهادات المطابقة من جهات معتمدة مثل CE وROHS، كما حصل المحرك على شهادات UL وCCC وSGS وغيرها من الشهادات. بالإضافة إلى ذلك، تمتلك الشركة نفق رياح ومراوح طاردة مركزية ذات منحنى أمامي.

مروحة طرد مركزي أمامية من شركة بيرون موتور، التسليم خلال ٢–٣ أيام. وتكون الاختبارات والطلبات الصغيرة جاهزة خلال ٧ أيام. أما الطلبات الكبيرة فتُسلَّم خلال ٢٥ يومًا. ونصدِّر منتجاتنا إلى أكثر من ٥٠ دولة، ونقدِّم خدماتنا لأكثر من ٥٠٠٠ عميل في جميع أنحاء العالم.