The fans are very key devices to allow air circulate from place to place inside the buildings and so on. They are vital to maintaining fresh, comfy air. Only two types of fans are in common use, namely forward curved fans and backward curved fans. Both of these fans allow air to circulate more effectively but both work in different ways and have their own benefits that make them useful for different scenarios. These fans are manufactured by a company called Beron-motor for various applications in various types of buildings.

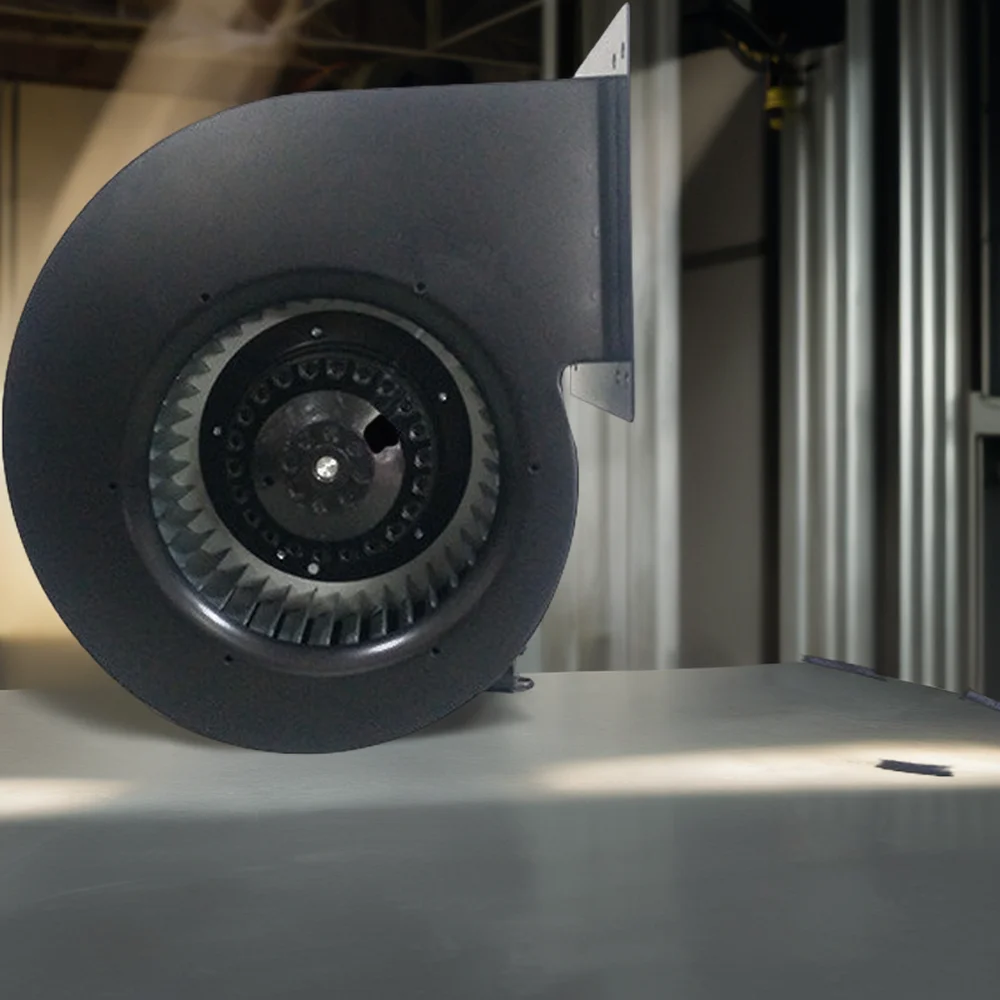

Squirrel cage fans are also referenced as forward curved fans. It has blades that curve with the direction of the air flow. This design is quite helpful as it enables the fan to move a significant amount of silent air. This is crucial in places such as hospitals and schools, where air exchange is efficient but has to happen without excessive noise. In addition, forward curved fans are highly energy-efficient, consuming less electricity to operate. It also makes buildings such as offices and schools less expensive to heat and cool.

Another advantage is that they are light weight. This makes them a piece of cake to install, allowing workers to throw them up without too much fuss. They are easy to install, so it also shortens the amount of time spent on maintenance jobs like cleaning or repairing fans. Beron-motor has different types of forward curved fans, which are widely used in air handling units in hospitals, schools, and other similar commercial systems. They help to keep everyone feeling more like at home.

Differences Between Forward Curved and Backward Curved fans To start with, forward curved fans are bigger and capable of picking up more air flow than backward curved fans. That’s why they’re commonly used in areas with high air movement requirements. Second, backward curving fan blades are more efficient in use which saves more electricity with having more air pressure behind. That makes them more efficient and better suited for buildings that require robust air systems.

Industrial fans are larger than most commercial fans, and these fans are required for an industrial ventilation system due to their size must be able to tolerate the specific airflow requirements of these massive facilities. Forward curved fans are excellent for ventilation systems that require high volume and low pressure air movement. This comes in useful for all those scenarios which need tons of air but without the need of to drive it too difficult.

On the contrary, backward curved fans are widely used in industrial ventilation systems that require to maintain high air pressure. They can force the air more and they also can run at a lower noise level.» These features make them great for industrial applications that require silence, like factories or warehouses. Backward curved Fans Beron-motor, used for factories, warehouses, and other industrial ventilation systems, are also available from the company.

Backwards curved fans, on the other hand, are more suitable for HVAC systems requiring higher air pressures. Examples of these systems can be seen in major malls, hotels, and various other large buildings where components of productive air flow are required. Beron-motor supplies forward and backward impact fans with high energy performance, which provide flow delivery in industrial premises. With such fans, buildings can make sure that all the people inside are comfortable.

Beron Motor's most forward curved and backward curved fan product EC DC AC External Rotor Fans Full Ranges. products widely used Fresh air system, heating, air conditioning ,refrigerations, air purification, telecommunications, electric power etc.

Beron motor manufacturer forward curved and backward curved fan 15000 square meters two factory centers. Beron motor manufacturer three product lines, including than 2000 models more 10000 different kinds spare components accessories can meet every customer's needs complete terms. Beron Motor laboratory located renowned university.

Beron Motor is accredited by CE ROHS CCC SGS and CCC forward curved and backward curved fan, CE ROHS, UL CCC and others certifications. We also have a Wind tunnels as well as a noises testing labs.

Beron Motor forward curved and backward curved fan times within 2-3days. Trials and small quantity orders will be ready 7 days. Mass orders delivered in 25 days. We exports our products over 50 countries and provides services to more 5000 clients worldwide.