Enter an Azatom. Have you ever walked into a site and smelled the stale musty air? This is necessary because it has to continue circulating air in order that a pleasant living environment can be provided and sustained. This is how important it is to control the use of centrifugal ventilators in these situations and ensure that there always be a good indoor air quality, such as ventilation density!

So, let the centrical pump world began... These fans bring in the air from one end and throws out through a vent or duct. A Department within )//eating, (0entilation and 1ir-.

It tends to be imagined that it would happen around a big factory or warehouse and surrounded by the cloud of dust produced as an indirect outcome from the machines, scheduled for storming in. It can be quite unpleasant! Insert a bad-ass centrifugal fan

This solution enables a huge radial ventilator to rotate at extremely high speed, effectively clean the polluted air and achieve very fast discharging speeds back outside from an outdoor exhaust channel. All the while, it allows fresh air from outside to fill that indoor bad one off so that there will always be a cost kickoff in the environment and real people can also take care of.

At the same time, masks are more critical in places like hospitals or laboratories demanding an environment free of germs without transmitting disease where a glial preserving gill air can be significant. Some good reasons to have a centrifugal ventilator.

By filtering and circulating air within a building, they work to clean the air - thereby reducing transmission of airborne pathogens (viruses, bacteria, allergens) while typically also improving the quality. They also function to stabilize the humidity and airflow conditions which are essential for medical gas management require a secure site where work is done both for patient safety as well as maintenance staff or researchers.

For instance, if you are going to install a centrifugal ventilator in any place of yours then it is very important for choose the correct type and size after considering so many factors. Many factors need to be considered before choosing a building including its size and where it resides or what function is built for; expected airflow rates vs energy-efficient.

Thus, the one which is going to work well for that office building hustle will not be such a big capacity as it would of use in case you had an immense industrial space there. Just as in cases of high levels of air pollution or very strict decibel limits a specialized and less noisy machine is required. Getting in contact with a professional HVAC engineer can assist you picking the centrifugal blower that is right for your specific application.

Did you ever wonder how centrifugal fans are powered and why these supply energy as well deliver up lots of cash? So want to know it in the eyes of science.

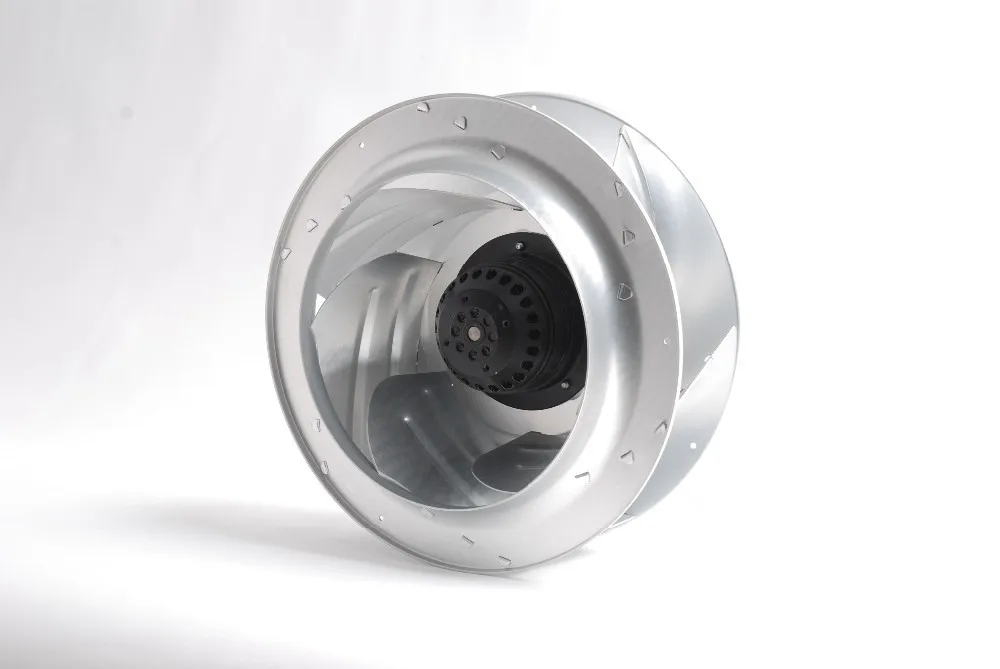

The centrifugal fans rotate their impellers to accelerate the airflow and generate high pressures than axial flow type fan. All these factors are affecting the airflow rate and pressure I will have: Blade shape, size and rotational speed. Engineers can improve this efficiency and save on operating costs by optimizing these various variables.

To further benefit, most moden centrifugal fans are equipped with energy saving features like - variable frequency drives that can modulate the speed of a fan based on load demand or actively controlled airflow and pressure regulators to geared by temperature profile (in case heating is needed), humidity controls but also air quality sensing. These features will not only save on energy, but they could also lead to a longer life of the ventilator and reduced maintenance costs.

To sum up, the part played by centrifugal fans is crucial to keep HVAC systems running smoothly and ensuring that comfort of us inside a building. If you using a centrifugal ventilator in the business, whether lockable industrial or commercial industry as well to choose energy consumption of materials could have an impact not only on human health but also environmental.

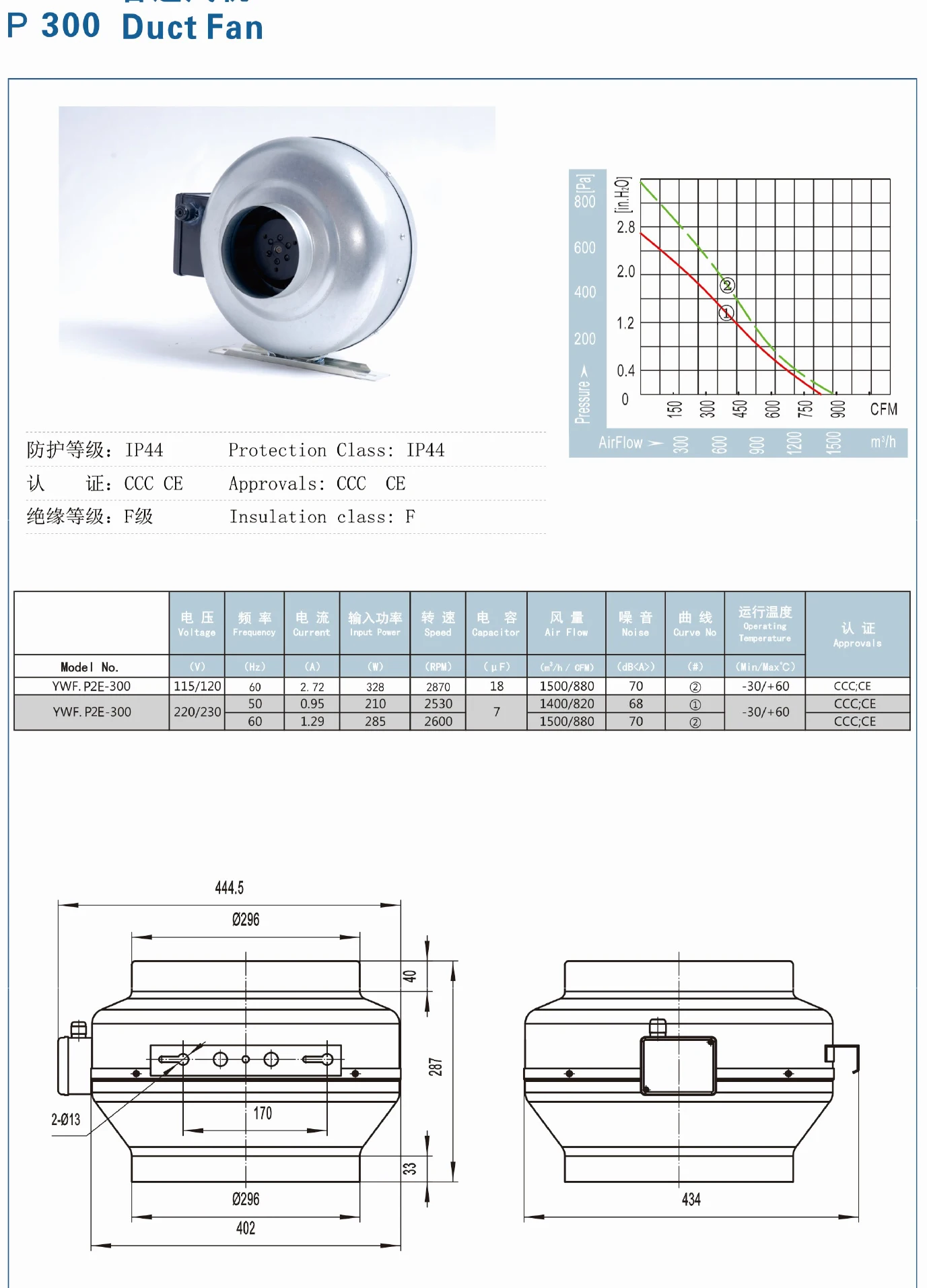

Beron Motor's most popular product line centrifugal ventilator DC AC External Rotor Fans Full ranges. products widely used Fresh air system, heating, air conditioning ,refrigeration, air purifications, telecommunications, electric power etc.

Beron motor promises trials time 2-7 days, 7 days small quantity orders, and triers orders. within 25 days bulks orders. We centrifugal ventilator to over 5000 customers around the globe and exports more than 50 nations.

Beron motor centrifugal ventilator covers 15000 square feet two manufacturing centers. Beron motor three product lines, which include than 2000 models 10000 types spare parts. Beron motor laboratory one famous university.

Beron Motor is a CE ROHS certified company. CCC SGS as well as CCC SGS, CE ROHS, UL CCC and others certifications. We also have a centrifugal ventilator as well as a sound test labs.